F.lli DEMARTINI owns three quarries situated in the Orero extraction site in Val Fontanabuona (near Genoa). The quarries, all underground, are equipped with modern cutting machinery thanks to which the blocks extracted come in perfectly regular, parallelepipedic shapes, unlike years ago. Over the years, the quality of the material from these quarries and the excellent technology employed have given the company a significant edge over competition. Slate from these quarries has a high level of fissility which makes the extraction process much simpler.

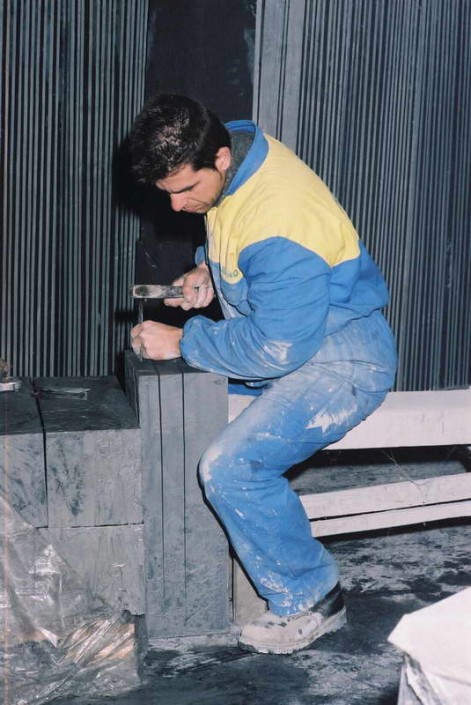

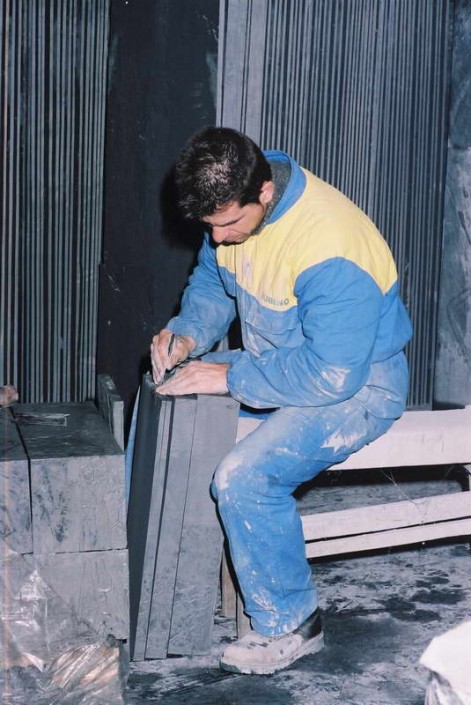

The technique of splitting slate into thin sheets, natural cleft or slatey cleavage, should be considered the first of the secondary phases when working slate and the key reason for its acquiring the importance it has been able to assert over the years. It is also important to consider that this particular technique has remained unchanged even in the modern work process, above all in the way slate is naturally split. Indeed it is interesting to note that Ligurian slate ‘splitters’ follow traditional methods, using the same tools as in the past and this applies even to the most up to date processing facilities. In order to achieve best cleavage results slate sheets must be kept damp. When a block of slate is ready to be split the slater places it between his legs and with a hammer and chisel cleaves and separates the sheets to the required thinness. As the sheets get thinner and thinner, splitting them with precision becomes more and more difficult, since the resistance of the sheets gets less and less as the cleavage process continues down to the last possible split. During block extraction, in order to make sure that splitting the slate along the plane of cleavage can occur at a later stage without fear of it hardening in the meantime, the stone is kept damp or rendered impermeable with ‘boiacca’, a muddy substance made of slate, dust and water.